Industrial printing market is undergoing a transformative shift with the advent of innovative one-pass UV technology. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Via rapid UV-induced ink curing, one-pass UV printing obviates prolonged drying and multiple runs, trimming both cost and time.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Superior resolution in single-pass UV yields finely detailed graphics and text, suited for packaging, signs, and marketing collateral. Also, this environmentally conscious tech consumes less energy than traditional printing, helping make production more sustainable.

Industrial printing market is undergoing a transformative shift with the advent of innovative one-pass UV technology. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Via rapid UV-induced ink curing, one-pass UV printing obviates prolonged drying and multiple runs, trimming both cost and time.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Superior resolution in single-pass UV yields finely detailed graphics and text, suited for packaging, signs, and marketing collateral. Also, this environmentally conscious tech consumes less energy than traditional printing, helping make production more sustainable. The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities.

The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities. Single-Pass UV Advancements

Digital high-speed printing historically pursues efficiency. In the past such jobs used multiple passes of ink, lengthening production and risking misalignment. Yet the arrival of Single-Pass UV is changing that landscape. With single-run UV curing, inks set instantly, offering remarkable enhancements in throughput and precision.Using Single-Pass UV yields bright hues with superb clarity and exceptional richness. This suits demanding uses like large-scale packaging, billboards, and promotional work where rapidity and impact matter. As the technology continues to evolve, we can expect even more groundbreaking advancements in Single Pass UV printing, paving the way for a future of truly high-speed, versatile, and cost-effective digital production.

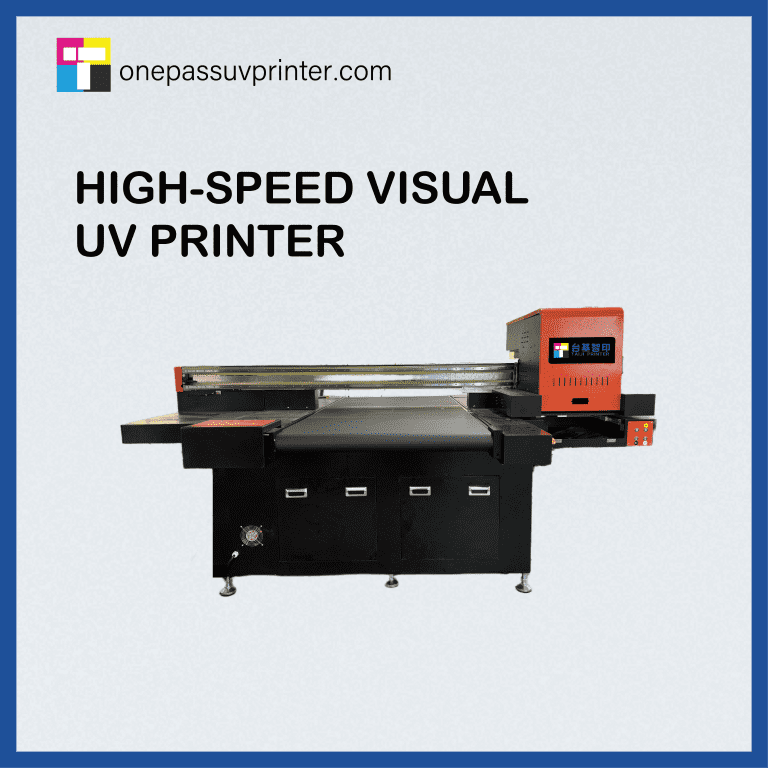

Single-Pass UV Printers: Next-Gen Throughput

Across the printing sector, single-pass UV printers now stand out as transformative tools improving speed, precision, and operational efficiency. These devices harness ultraviolet curing to set inks rapidly, enabling very high production rates. With their ability to print multiple colors in a single pass, single-pass UV printers offer unmatched resolution and vibrant color reproduction. From personalized items to large commercial print jobs, these printers handle numerous applications to meet growing customer expectations.Elevate Your Printing Process

Expect to be impressed by the single-pass UV printer — a strong solution transforming industry norms. This clever device leverages UV light to fix inks in one pass, attaining remarkable quality and resolution.- Benefit from bright tones with exceptional detail

- Boost your production speed with rapid printing capabilities

- Embrace new creative freedom across diverse surfaces

Fast-Track UV Printing: Delivering Unmatched Efficiency

UV printing has changed the graphics landscape through faster production, precision, and strong color reproduction. Still, speed-optimized UV printing enhances these strengths, offering unprecedented production efficiency. The tech leverages purpose-built printers that output high-res images extremely fast. Thanks to instantaneous curing and minimal dry time, rapid UV printing optimizes processes enabling easy fulfillment of demanding jobs. High-speed UV advantages go further than simple efficiency gains. It produces top-tier print results, long-lasting durability, and versatile application potential. From packaging and large-format banners to labeling and promotional signage, rapid UV printing alters business processes to support innovation and market leadership.

One-Pass Production: The Ultimate Solution for Fast Turnaround Times

In a time-driven market, speed is crucial. For printing, businesses require fast, efficient solutions. This is the promise of One-Pass Print. It enables single-pass printing to avoid multiple runs and shorten total processing time. With One-Pass Print, you can enjoy significantly faster turnaround times, freeing up your valuable time and resources. Hence, businesses of varied sizes can capitalize on One-Pass Print advantages. From promotional pieces to critical documents, the tech enables timely printing without sacrificing quality.The Fusion of Efficiency and Precision in UV Printing

In contemporary production settings, efficiency is essential. Producers want solutions that keep quality high and production fast. Single-pass UV surfaces as a pioneering solution tying high-quality inspection to quick curing. This innovative process employs ultraviolet light to instantly cure inks and coatings, resulting in vibrant, durable finishes while minimizing production time. Single-pass UV’s accuracy results in single pass uv printer flawless goods meeting demanding quality norms. The benefits extend beyond enhanced quality and speed. Single-pass UV minimizes waste by avoiding extended drying cycles, promoting sustainable operations.- Moreover, single-pass UV’s flexibility allows use across many sectors, from packaging and print to electronics fabrication.

Upgrading Digital Printing with Rapid UV

The printing industry is continually evolving, driven by a constant demand for faster speeds, greater precision, and innovative solutions. High-speed UV technology has emerged as a game-changer, offering a powerful blend of these essential elements. UV printing utilizes ultraviolet light to cure inks instantly, eliminating the need for lengthy drying times and opening up a world of possibilities for printers. Fast UV cure produces high print rates, cutting production time and elevating operational efficiency. Besides, UV inks provide excellent durability and protection from fading, abrasion, and water, making them broadly applicable. From colorful signage to durable product packaging, fast UV printing is redefining printing standards.- Pros

Instant Print Era: One-Pass UV In Practice

In rapid-design and imaging contexts, time is extremely important. Clients require speedy fulfillment and companies must deliver premium prints on demand. Here one-pass UV devices deliver transformative solutions for current printing demands. Advanced systems apply UV inks that cure immediately under illumination, removing drying wait times. Result: immediate prints showcasing lively colors and robust finishes. Hence, one-pass UV systems see adoption across broad industry contexts. From retail and e-commerce to marketing, photography, fine art, and manufacturing, companies adopt instant printing. Typical applications include bespoke product printing, tailored signage, and compelling promotional items. The benefits encompass more than just speed and operational efficiency. Single-pass UV printers ensure accurate color, fine resolution, and substrate flexibility for rigorous projects.- Furthermore, single-pass UV is sustainable because it uses no harsh solvents or VOCs.

- Ultimately, the age of immediate prints is now; thanks to speed, versatility, and fidelity, one-pass UV is remolding print workflows for efficiency.

Upgrade Workflow with Single-Pass UV

Rationalize production flow and gain enhanced efficiency through single-pass UV printing. This advanced method enables bright, high-res printing directly on many substrates in a single pass, removing multi-step layering.- Secure extraordinary speed and decrease production time.

- Increase output via faster order processing.

- Use UV ink’s durable precision to secure long-lasting vibrant prints.

Single-Pass UV: Boosting High-Impact Print

Single-pass UV has changed the landscape for high-impact printing. The technique applies ultraviolet curing for inks, offering notable improvements over legacy methods. To start, the method secures outstanding image quality by producing vivid hues and crisp detail. Instant curing removes drying intervals, leading to higher productivity and quicker turnarounds.- Furthermore, single-pass UV printing is known for its durability and resistance to fading, scratching, and abrasion.

- Ultimately, the mix of superior image fidelity, improved productivity, and robustness positions single-pass UV as an excellent high-impact printing solution.